Introduction

The Research Laboratory at the Geological Survey of Finland consists of roughly 20 highly trained staff, preparatory mineralogical and geochemical laboratories, and cutting-edge instrumentation ranging from X-Ray devices (XRD, benchtop XRF, scanning micro XRF and XCT) to electron beam devices (electron microprobes, FE-SEM, LV-SEM) to mass spectrometers (Single and Multiple collector mass spectrometers each with Excimer lasers). Linking together the capabilities of these instruments provides us the means to make multifaceted studies of a diverse range of projects. Many of these capabilities are being put to good use to solve challenges provided by the MinExTarget project.

The MinExTarget project was created to develop a commercial exploration tool for exploration in a variety of landscapes, including those covered by glacial materials, or those containing river and even shallow marine sediments. In Finland, as elsewhere in Northern hemisphere countries, under the weight of massive, slowly moving sheets of ice during the last ice age, bedrock surfaces were abraded and ground by the ice, partially pulverizing material from the rock surface, carrying this material some distance in the ice flow direction and finally depositing it as an unsorted, unconsolidated sediment called till. Till is practically everywhere in Finland, and therefore exploration techniques must be able to look through this layer of sediment by geophysical methods or decipher from the pulverized bedrock material in the till itself, what type of rocks and mineralization exist in the up-ice direction from any given sampling location.

Initial Sample characterization

The samples our laboratory began work on in October 2020 had been taken by shovel from the target area in Lapland, and then transported to the University of Oulu where they were preconcentrated using a Knelson Concentrator (producing so-called precons). After receiving the precons, the Research lab went to work characterizing them, measuring their chemical and mineralogical composition using XRF and XRD respectively. Since sulfide was the target mineral, the idea was to see if S concentrations correlated with sulfide content, and so the hunt for the most sulfur-rich samples ensued. In the end however, the sulfur concentrations in the precons turned out to be so low that we could not differentiate among them using this method. Consequently, a dozen precon samples were chosen, sieved to various grain sizes, and tested by microscope and SEM scanning (see below) to see if this level of concentration could possibly provide adequate grains of sulfide without further processing. However, since not even a single grain of sulfide was discovered in these initial 12 grain mounts, it was decided further sample treatment would be necessary.

Further Sample Preparation

Since the MinExTarget project in Finland focusses on the heavy mineral fraction of till to gain information on mineralization types up-ice, proper processing of the till to separate heavy minerals is critical to the entire process. If the heavy minerals are lost during processing, the entire chain of work that follows can be considered wasted effort and wasted money.

Along with partners at Palsatech and CRS, GTK research laboratory personnel have been testing a range of different Heavy Media solutions at various temperatures to try to devise the best method for separating lighter and heavier fractions. MinExTarget has the additional goal of trying to move away from the most toxic media, to newer, more environmentally and user-friendly solutions. Our goal is to make heavy mineral separations that give the cleanest concentrate with the fewest low-density grains whilst losing no important high-density grains. The smaller the volume of resulting concentrate, the less mass of material needs to be studied to find the grains of interest. This translates into making and analyzing fewer grain mounts per sample, thus streamlining the workflow.

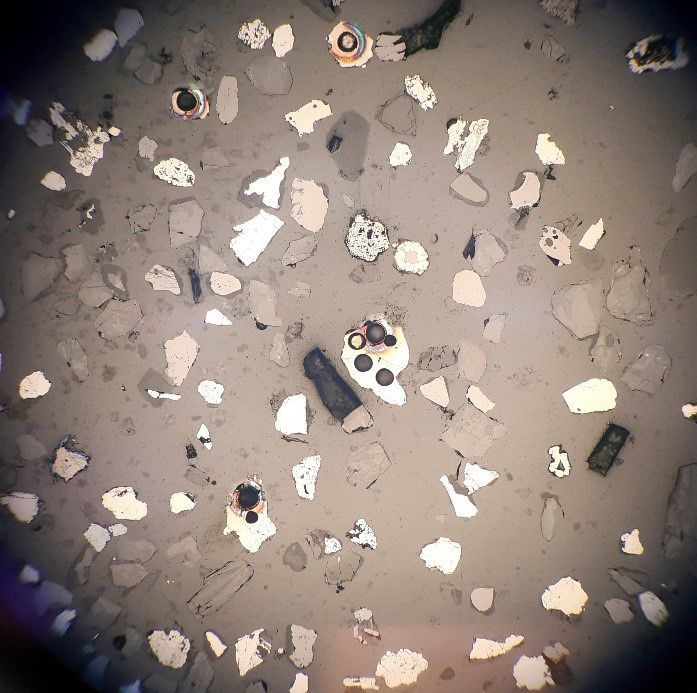

Sample mounts are made by carefully sprinkling the heavy mineral concentrate onto a circular piece of tape with an attached 2.5 cm mold, and then tapping to carefully produce a monolayer of grains. Mixed resin is then poured into the mold from one side, slowly building a layer of bubble free resin that fully surrounds the grains, embedding them in hard epoxy after treatment in a warm oven. The resulting epoxy mount, when removed from the tape, is then ready for very careful grinding, just enough to expose the centers of the grains, and then polishing.

SEM studies

Epoxy mounts of the heavy mineral concentrates (like those from the precons described earlier) were placed into the Low Vacuum (LV) SEM and scanned using automated mineralogy programs in the Inca software package to find all grains above a specified grey scale (the brighter the grain, the higher the mean atomic weight of the mineral). Unfortunately, the SEM scans provided only rare sulfide grains, supporting optical microscope inspection results that also indicated rare to no sulfide grains. Measuring trace elements on sulfide grains from the test area was going to be a problem.

Alternative Plans

Two alternative plans were conceived to solve the dilemma of the missing sulfides. The first was to look at other till samples known to be rich in sulfides, in this case the Häme belt area in Finland, and potentially use this area as the test case instead. Existing mounts with large quantities of sulfides were scanned by LV-SEM to locate grains, the coordinates of which were then transferred to the LA-ICPMS for ablation and trace element analysis. Many hundreds of analyses, at various spot sizes to test what constitutes an adequately sized grain, were generated. Unfortunately, however, there is no large-scale active exploration going on in the Häme area currently, so impact of any MinExTarget outcome could not be optimally tested. The second plan was to go back to the till samples from the test area and choose other minerals to target. Scheelite and monazite occur in both the mineralization at Rajapalot and in the till in the area. This second plan is now ongoing and will continue with determination of the trace element composition of the scheelite from source rocks and till and test whether they can be shown to have a common origin, which ones are related to gold mineralization and whether there are other unknown scheelite types in the till. For monazite, U-Pb ages will be measured to determine if the till areas with the correct Au-related mineralization ages exist. In both cases, if results are positive, they will help define drill targets for next winter’s drill program by our partner Mawson Gold Ltd.

Figure 1. Separation funnel with LST solution loaded with a till precon to separate the light minerals (the floats) and the dark heavy minerals (the sinks).

Figure 2. Reflected light photomicrograph of an epoxy mount of the heavy fraction from a till sample from the Häme area, Finland showing abundant sulfide grains (brightest), some of which have been laser ablated to determine their trace element composition.